The extended footpegs on my wife's Kawasaki 1600 Vulcan need to be improved. My wife is tall and when we ride together, with the stock footpegs on it, my wife's knees were almost up in my ribs and in severe pain after a full day of riding. Awhile back I "engineered" footpeg extensions that go out over the large pipes on the motorcycle and extend forward about 6 inches. Anyways, it's finagle time, and I know just the finagler to do it!

I purchased a welder early last year and haven't had any relevant projects to use it on until now. This is a task that has been on the back burner for some time, and with our schedule clearing up a bit, now is the time to work on it.

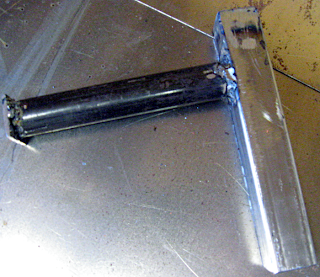

This is the footpeg that is getting reworked:

|

| Someone needs to wash those pipes... |

Only not, because I will tell you about all the surprises I get hit by as I do this project.

To start, I cut my square tube and the plates to cap it and the plate to fill in the mounting indentation:

This is before welding. Keep this in mind: of all the machining and fabrication I have done to date, welding is the one trade I have done the least. Even though I read the manual to be sure it was as simple as it seemed, using a machine that generates enough electricity to fuse metal is nerve wracking. It also means my welds will be terrible until I learn my welder.

Here are the first pieces together:

Those are some UGLY welds, but the parts definitely came together well. A good grinder, sander, and painting will hide all that, though. You'll see!

I checked this part against the motorcycle mount:

Clears the pipes well enough! I also designed it to have that 1 inch rise on the upper square tube so that the passenger's foot is less likely to slide off the upper peg. I now have a permanent forward angle and the mounting indentation is filled out with the square plate to stop swinging from that point.

Now to the footpeg going onto the extender:

Well this isn't good. The bolt didn't reach through the square tube! I just hit a major snag and even though I quickly engineered an answer, my one day project is now a two day job. To solve this, I would have to cut and drill out the bolt and install a new one. I would also have to tack weld it to imitate the original bolt design. Here's what it looked like:

I ended up sanding down the bolt head so that the pivoting action of the footpeg wouldn't be blocked. It worked great!

Almost done! One last task to make these footpegs look amazing. Paint! Gotta cover those awful welds, after all.

|

| Primered... |

|

| ...painted! |

Onto the motorcycle they go. This is how one looks:

|

| Pipes still need cleaning... |

My joy is in this work, even if it is improving what was there. What I experienced is this...

"It is the gift of God whenever anyone eats, drinks, and enjoys all his efforts. I know that all God does will last forever; there is no adding to it or taking from it. God works so that people will be in awe of Him. Whatever is, has already been, and whatever will be, already is. God repeats what has passed." [Eccl. 3:13-15, HCSB]

Live a joyful life for God and His Son Jesus Christ. Because there's nothing new under the sun; what seems new has already been done.