While I was living in Washington and Colorado the most use it got was target practice. It's powerful and fun to watch the shockwave come off the muzzle when a friend shoots it in the prone position.

Now I live in Texas and this year I have taken this rifle white tail deer hunting. I put down my second deer with this rifle, an 11 point buck on my father-in-law's property. (On a side note, everyone wants to hunt on his property now!) Now, part of the AR-15 fever is not only about the gun law revision that may or may not happen in the near future in this country, it's about the rifle accessories you can put on an AR-15. Illuminators, laser targeting, night vision, bipod, etc. I could not do that with this gun, and two years after I bought my Saiga rifle, Saiga Arms was bought out by Remington.

I had heard that there are companies that still made aftermarket parts for the Saiga .308 so I checked a few websites. Initially I didn't understand what I was looking at or what some of the terms on the websites meant, so I wasn't encouraged by some of the $300 price tags I saw. I decided to go look into gun forums and found the exact names for the parts I was looking for. I went back and entered those names and what a difference! $55 for a pistol grip buttstock and $65 for a hand grip that takes rail mountings!

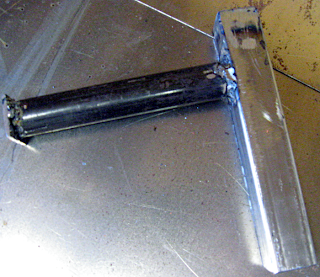

The process of changing the hand grip and butt stock was interesting. All the butt stock instructions say about removing the old stock is "remove the old stock". It didn't tell you about a hidden screw under the spring latch cover! Luckily I didn't man handle the rifle but instead ran to the internet to get an answer. I removed the hidden screw and after sanding down one screw a little, I got the stock changed and tight.

On to the hand grip. One of the screws needed to be sanded down a bit. Be forewarned, it didn't come with any allen wrenches so if you do this conversion, make sure you have a good set of hex wrenches. This is the gun with both pieces on it.

Looks great! Now to show what it will look like fully ready.

The love of the Lord Jesus be with you this next year, and God bless!